At Fleetwood, We are no strangers to equipment that requires special treatment, finishes and handling. We do work for a variety of Food, beverage and pharmaceutical customers on many different types of equipment.

We also carry multiple lines of sanitary and food-grade pumps, mechanical seals, homogenizers, lubricants and barrier fluids, washdown-duty motors and much more!

Food, Beverage and Pharmaceutical

Flowserve Durco Mark III, FRBH and LR Pumps :

The hygienic volute casing pump is designed with an open impeller (for optimized pumping of shear-sensitive media) rotating on a robust shaft. The thick-walled stainless-steel casing is fixed by a sturdy quick-release clamp ring with sanitary grade O-ring sealing. All process-wetted parts are constructed from electro-polished AISI 316L stainless steel. Importantly, the volute casing is rolled steel, while the casing cover is forged in order to provide a heavy-duty construction. All other parts are made of AISI 304. The pump range is in accordance with food-grade standards 3A1 with a surface roughness Ra<3,2 µm (other standards are optional). The modular and compact design, use of standard motors and several options guarantee reliable performance within the food and beverage industry. Hygienic centrifugal pumps are used within the F&B industry in breweries and dairies. Application areas for these pumps include brewing (mash, wort, beer); dairying (milk, cream, fats); filtration (filtration, separation, mixing); cleaning (up and downstream CIP); filling (beer, soft drinks, juices); and sterile and pure water.

Flowserve SIHI Vacuum Pumps for process vacuum applications.

Some of our offerings for the Food and Pharmaceutical Industry include:

Flowserve Pumps and Mechanical Seals

Flowserve ISC2-BBW, BX, P-200, P50, RO, CPM and mixer seals as well as seal support systems for food-process dairy and sanitary applications.

Flowserve Packages:

Flowserve offers two main packages for bottle filling. They are SIHI sanivac and SIHI compact. Along with the SIHI sanivac and the SIHI compact, standalone LRVPs are also used. Larger breweries use the LPH 65320 and 65327 for their fillers; many craft and microbreweries use the smaller LEM range. For some duty conditions, you will also find a range of ISO pumps for the CIP and hygienic pumps in abundance for the process. CIP is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly. Up to the 1950s, closed systems were disassembled and cleaned manually. Slurry pumps can also be found handling residue product

CIP and SIP Processes:

Grundfos CIP pumps can handle high temperatures and are made of stainless steel, so they can withstand the aggressive chemicals, disinfectants and detergents encountered in cleaning processes. Because the CIP system is never in contact with the actual process, sanitary pumps are not required. Additionally, CIP pumps are electropolished to make sure no residue sticks to the inside. Tanks, pipes or process lines can be efficiently cleaned without dismantling any equipment, saving time and money. For the more demanding SIP process, Grundfos range multistage pumps are used to feed the boiler that produces the steam and efficiently cleans at very high temperatures

Hydro HP Washdown System:

The all new Grundfos Hydro HP is a fully integrated high-pressure booster system that offers a more reliable and energy-efficient solution for clean and wash applications. The system features the industry-leading CR vertical multistage inline pumps, which deliver superior hydraulic performance and bulletproof reliability in a space-saving footprint. The integrated VFD control offers consistent system pressure, whether the system is used to clean with one spray wand or do a full facility washdown, all without the need for a recirculation line. A low-flow jockey pump efficiently maintains system pressure to meet low-flow cleaning demands Additionally, with the easily serviced Grundfos Hydro HP, plants can expect to realize full ROI after the first few maintenance cycles.

Dosing:

The Grundfos dosing and disinfection product range covers everything from the disinfection of drinking water to antimicrobial washes. With one of the most extensive product ranges of pumps, packages and accessories in the market, Grundfos dosing and disinfection products deliver accuracy, reliability and safety in an area where processing plants can’t afford errors

Ampco’s diverse line of Sanitary Centrifugal and Positive displacement pumps as well as Homogenizers provides equipment for just about any food-grade application.

Ampco products are available with a variety of metallurgies and finishes making them ideal for dairy, brewery and food applications.

The versatile HL Series Homogenizer design offers improvements to extend the life of common wear items and shares many common parts and a similar footprint with pre-2000 competing brands like Gaulin.

Ampco also has a tremendous inventory of interchangeable homogenizer repair parts in-stock compatible with competing brands like Gaulin. Mobile service technicians are on-hand to ensure your equipment stays running smoothly too.

-

Lobe Pumps

We have worked on a variety of Lobe pumps including Tri-Clover, Ampco and Tuthill. We are an authorized Ampco distributor and can get any part for your Ampco lobe pumps as well as SPX Flow / Waukesha Cherry Burrell Universal I and Universal II Series or Wright TRA10 and TRA20 style pumps.

-

Gear and Roller Pumps

We work on all kinds of gear pumps and have seen everything from Flowserve/Worthington, Viking, MASOSINE, Gorman Rupp, Oberdorfer and everything else! We also carry and manufacture several lines of aftermarket parts which are far more cost effective than OEM.

-

Centrifugals

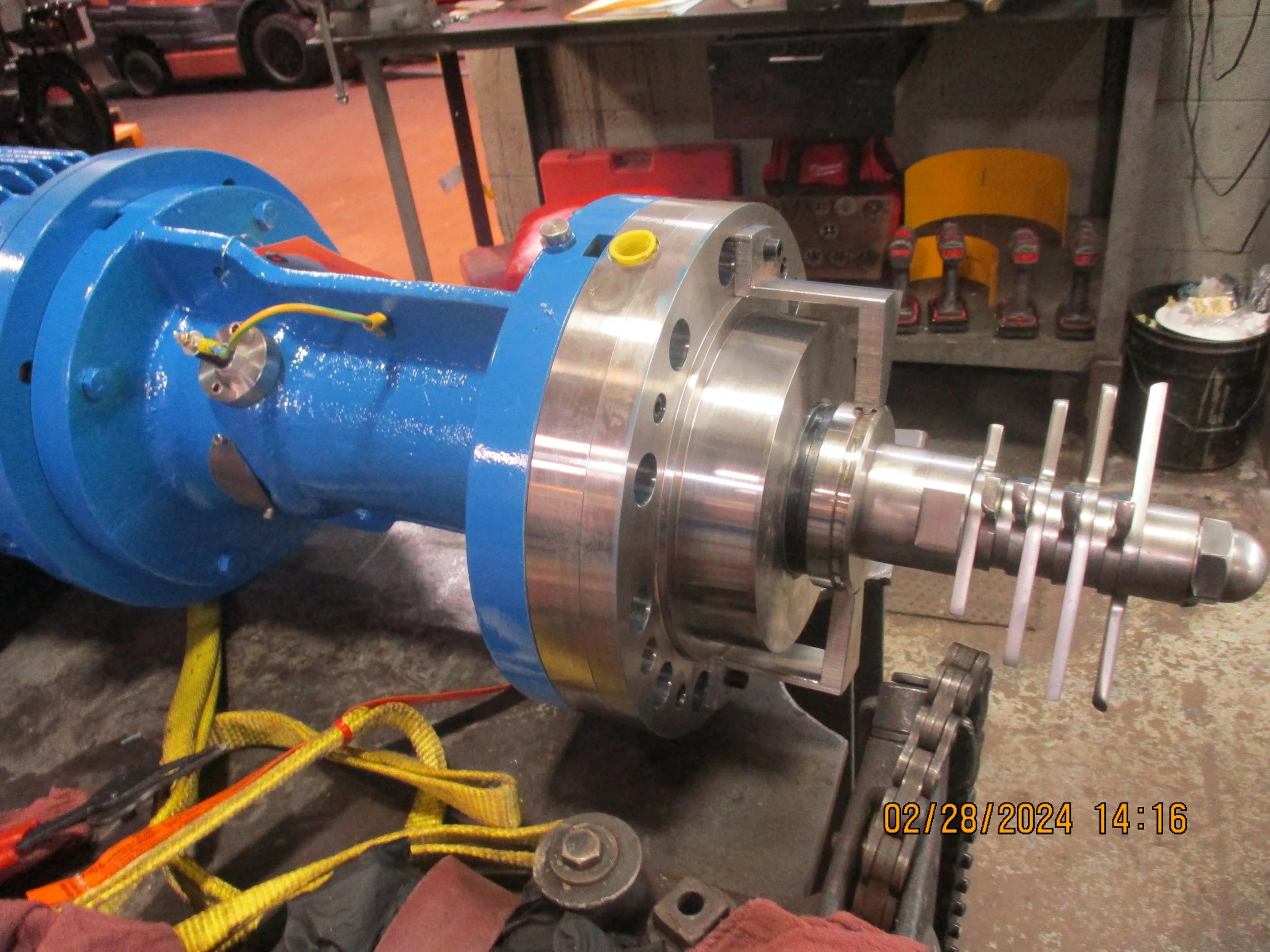

It is well known that Fleetwood has a vast experience rebuilding centrifugal pumps over our 38+ years in business, and food-grade equipment is no exception.

We rebuild and manufacture parts for all brands of centrifugal food-grade pumps.

We also stock a number of Stainless-Steel Flowserve Mark III pumps as part of our kit program and can have a pump ready to install in a matter of days if in our stock!

-

Mechanical Seals

Fleetwood’s mechanical seal experience is unparalleled by any local company. We have the most knowledgeable engineering staff in the Delaware Valley backed up by the reputation and quality of Flowserve.

We can rebuild and convert all kinds of mechanical seals including mixer seals!