Fabricated Vertical Pump Motor Stand

Stainless Steel Overlay Extends Life of Boiler Feedwater Pump

-

A customer was experiencing short life on their boiler feedwater service. Customer has (2) Ingersoll Rand 3x10DA-7 stage pumps in service. Normally one pump runs and one pump is in standby.

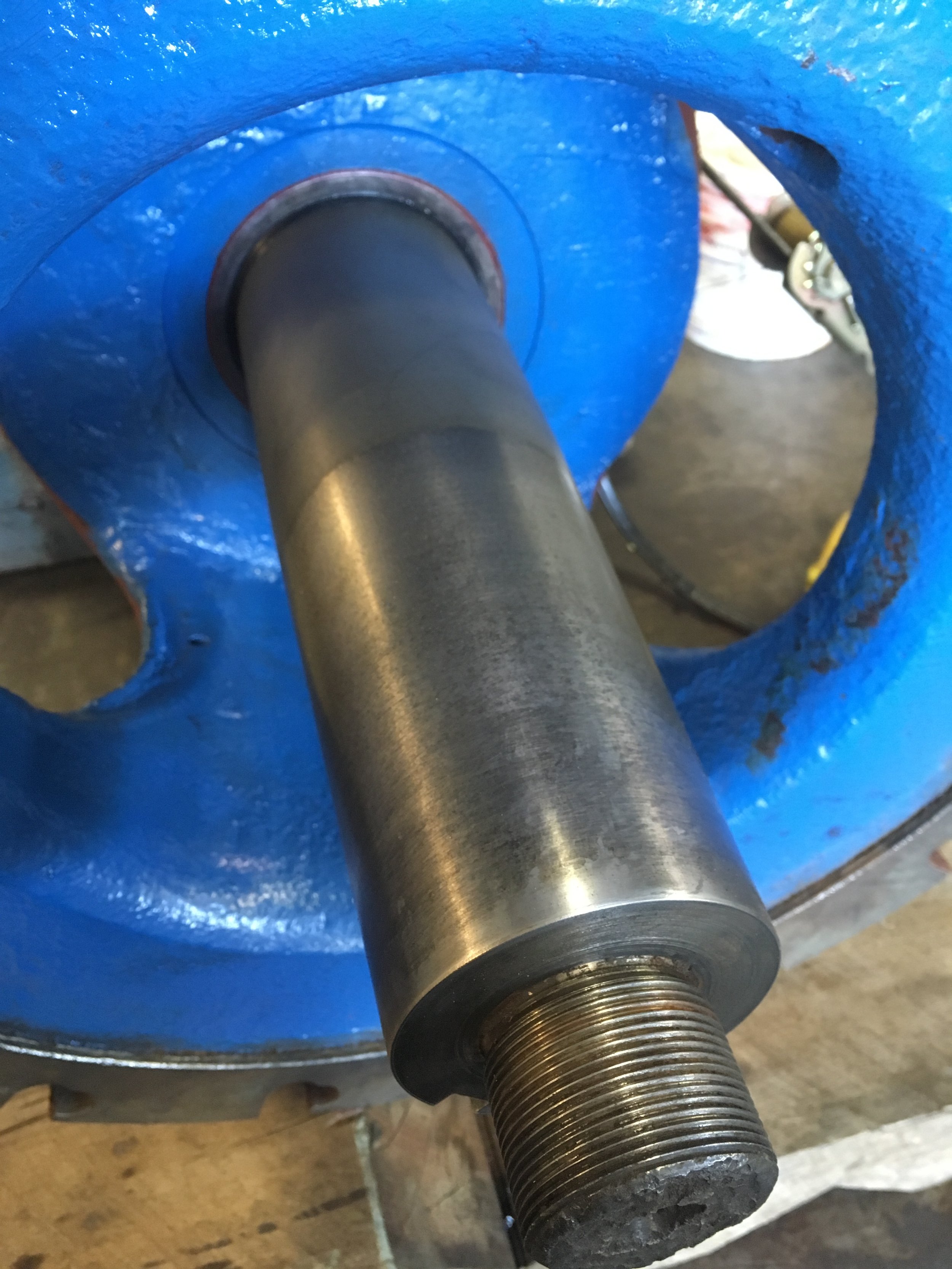

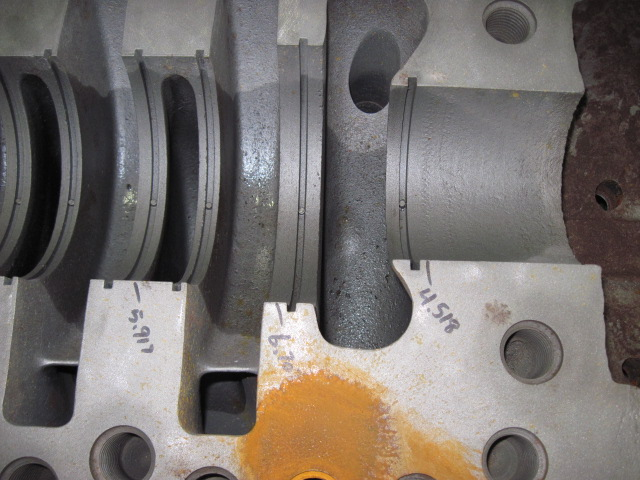

The pumps have a carbon steel casing. The impellers, sleeves, and bushings are 12 chrome. The wear rings were cast iron. We repaired these two pumps 5 times over a 3 year period from June 2008 to June 2011. Some of these repairs were for operational issues, some were for performance issues, but always we found that internal case fits and wear rings clearances had opened up due to corrosion. Corrosion of the casing was bad enough to require a planing the split and reboring the casing.

-

We could see that the boiler feedwater was corroding the carbon steel and cast iron parts while the 12 chrome stainless parts were not being attacked. For this reason, customers often purchase 12 chrome casings in boiler feedwater service, but a 12 chrome casing is an expensive option. A new 12 chrome casing costs over $500,000.

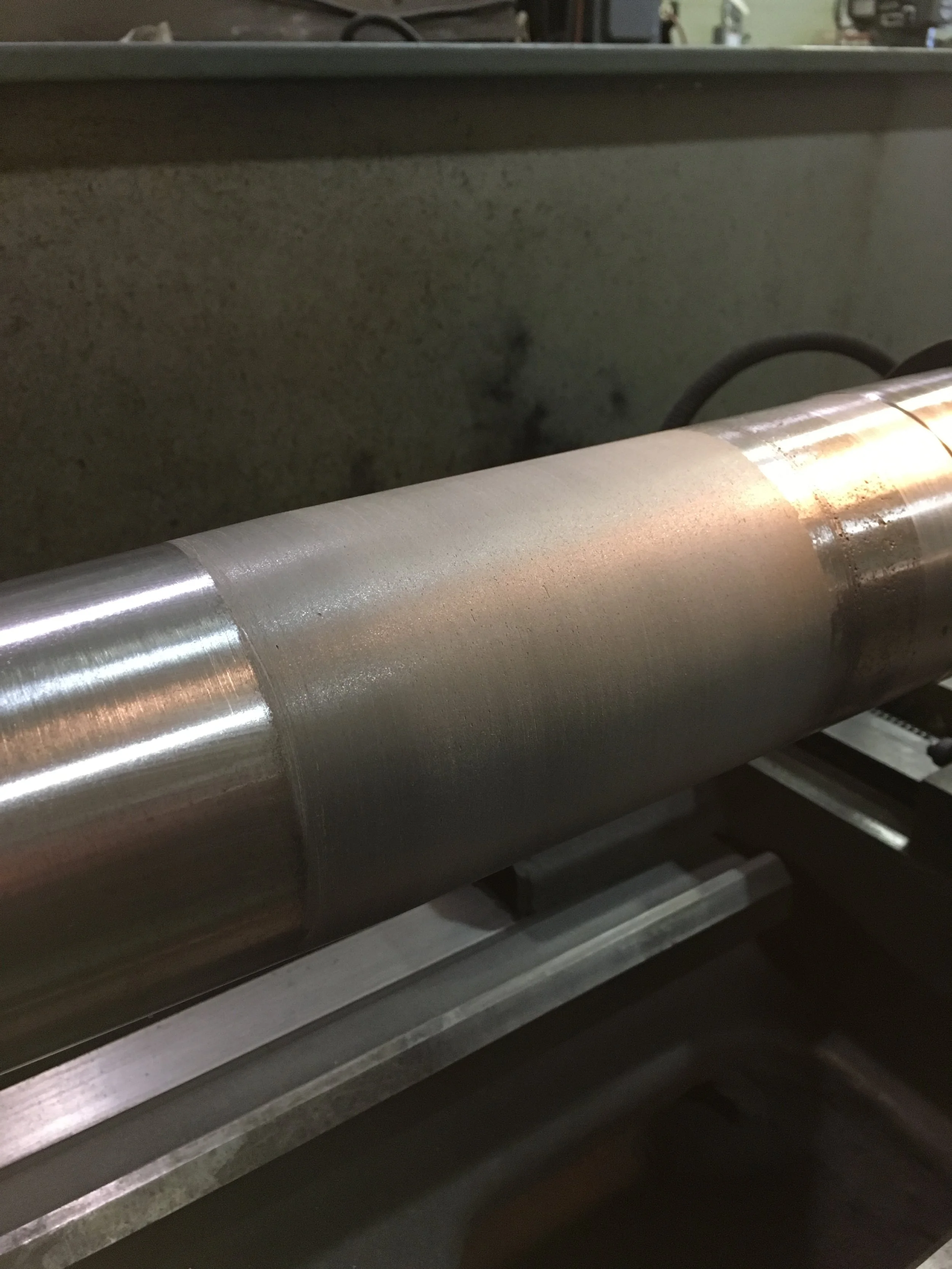

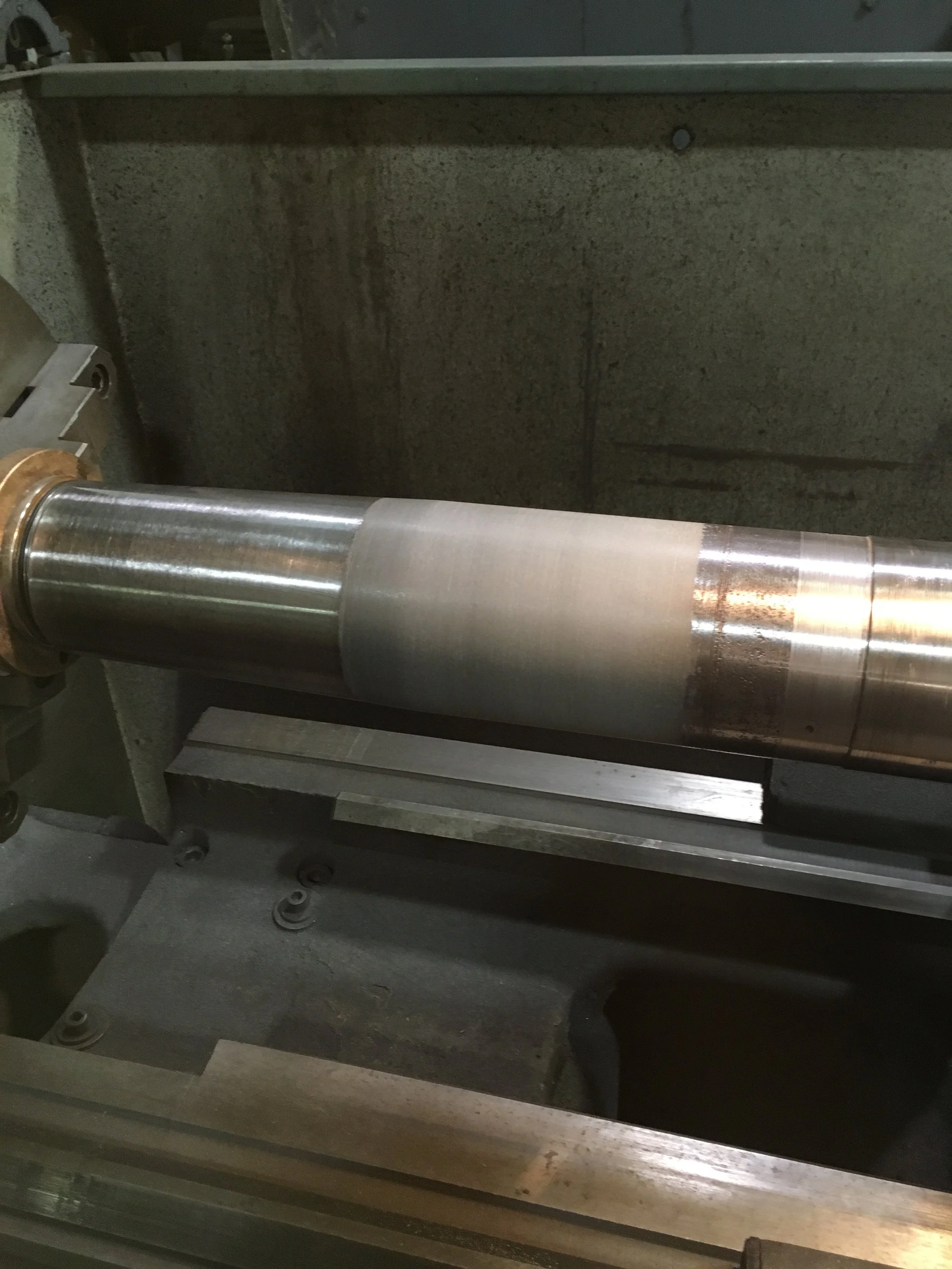

To fix the problem, we machined out the internal casing fits built up the fits with 300 series stainless steel weld overlay. We then planed and rebored the casing. Cost of the casing work was ~ $35,000, much less than the cost of a new 12 chrome casing. We also upgraded the cast iron wear rings to 12 chrome stainless steel.

Both pumps are in and running with no reports of any drop-off in performance.

Ceramic Coating for Erosive and Cavitation Wear

Our customer’s critical line pump suffered a massive power end failure. Fleetwood’s DCSC shop was able to source parts and rebuild the pump while also upgrading the power end to have a lower L/D ratio within a week of arrival! Customer was back up and running!

Flowserve API Pump Emergency RVX Upgrade

Metal Repair Paste Coating on Shaft for Damaged Seal Area